Everyone thinks they’re an expert these days, they have a quick google, and Robert’s your mothers brother, they think they’re an expert. This even applies to the trades, how many times has a customer asked you for something, and then tried to source the materials themselves? It can be a minefield in lost jobs trying to convince a customer they’re backing the wrong horse. They think they’ve found it cheaper, or worse when they think you’re trying to rip them off when they’re comparing budget options to premium high-end gear.

The same goes for floor heating, particularly in the over floor market. With so many boards to choose from it helps to have the facts to steer your customer to the best solution. Recently the market has been saturated with low-quality EPS boards. These boards aren’t low quality because they’re made of EPS, it’s the lack of the material itself that makes them low quality.

This doesn’t mean cost is a signifier of quality either. Various retailers will charge “competitive” prices for their over floor board whilst omitting the strength or heat spread statistics from the product page. With that in mind it’s not uncommon to find lower quality products priced as though they’re competing with the premium quality ranges available elsewhere.

So we know cost doesn’t signify quality, and we know there’s a lot of rubbish out there, so how do you know what’s worth paying for? Well it comes down to the tech specs, specifically the board strength and aluminium thickness which will enable your floor to heat efficiently.

Board strength is an important consideration when choosing over floor solutions, typically measured as compressive strength in KiloPascals (kPa). Most EPS boards on the market are made with 100kPa EPS, which isn’t far off the spongey packing polystyrene you get with deliveries. Leading to suppliers advising you to purchase a strong backer board for stability before you lay the floor finish. If you’re not looking to waste your time and money on backer boards you need something that’s at least 200kPa strong.

The main issue for the consumer is there are no visible differences between 100kPa and 400kPa polystyrene boards (400kPa is approved for tiling directly onto by some tile adhesive manufacturer’s). Be sure to do your homework and check the tech specs, if it doesn’t say what kPa the board is, then assume the lowest quality.

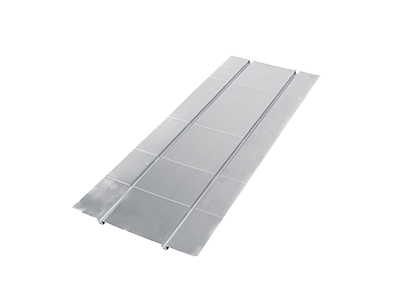

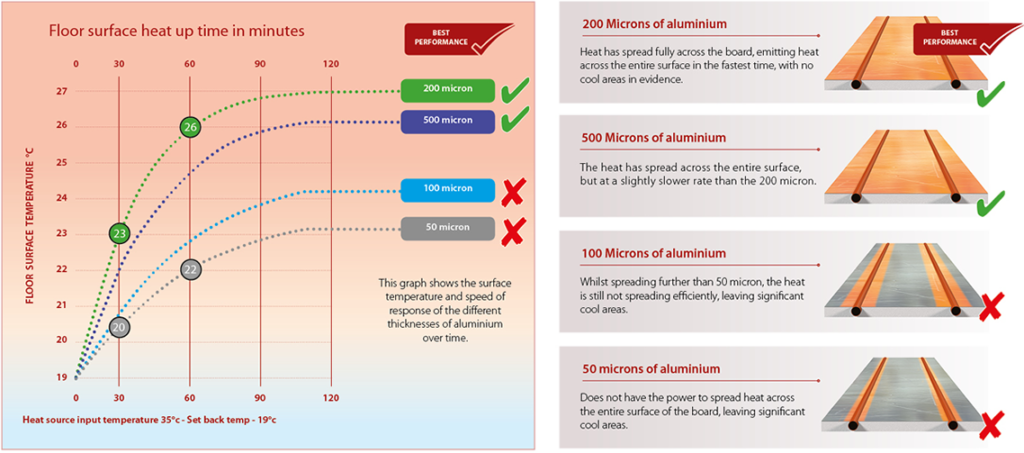

The second thing to consider with an overlay solution is heat spread. You need to assess the aluminium that comes on the board. Typical polystyrene materials like EPS or XPS have great insulation properties. They hold the heat in position and don’t allow it to escape down or out. Which means they need a good conductor to carry that heat right the way across the board quickly. Otherwise, it will only heat the floor where the pipes are and you will have cold spots.

Aluminium is a great conductor, and is available in a variety of thickness’ that are measured in microns (0.001millimetre = 1 micron).

Fig: 03 – Effects of aluminium thickness on heat spread distance over time.

As you can see from fig 03 – 200 micron is the optimum thickness for heat spread any less and you risk cold spots and a slow heat up time.

Most manufacturers are aware of how aluminium works, it’s just cheaper in production to use less, and it looks the same; so again make sure you check the specs, if it doesn’t say how thick the aluminium is, it’s probably too thin to work effectively.

As you can see separating the fact from the fiction isn’t always straight forward, and in today’s world it’s just as easy to become misinformed as it is to be well informed. Do yourself a favour and look past the flashy claims, look at the facts and check the tech specs after all it’s your reputation on the line – and if they don’t tell you what kPa the board is or how thick the aluminium is, look somewhere that will.

Paul Simmonds