Wunda OVERFLOOR heating boards have revolutionised the floor heating industry with a wide range of heating solutions that will suit all styles of housing. New Build, Renovations and Extensions, single rooms, whole house, offices, flats, cabins and even boats.

Tom Edmunds, Product Development Manager at Wunda Group explains the latest developments in this increasingly popular way to heat the home.

Wunda OVERFLOOR heating will increase the value of a home and can be easily installed over any existing sub floor with minimal disruption. Suitable for most floor finishes, with low running costs, efficient heat distribution and rapid response.

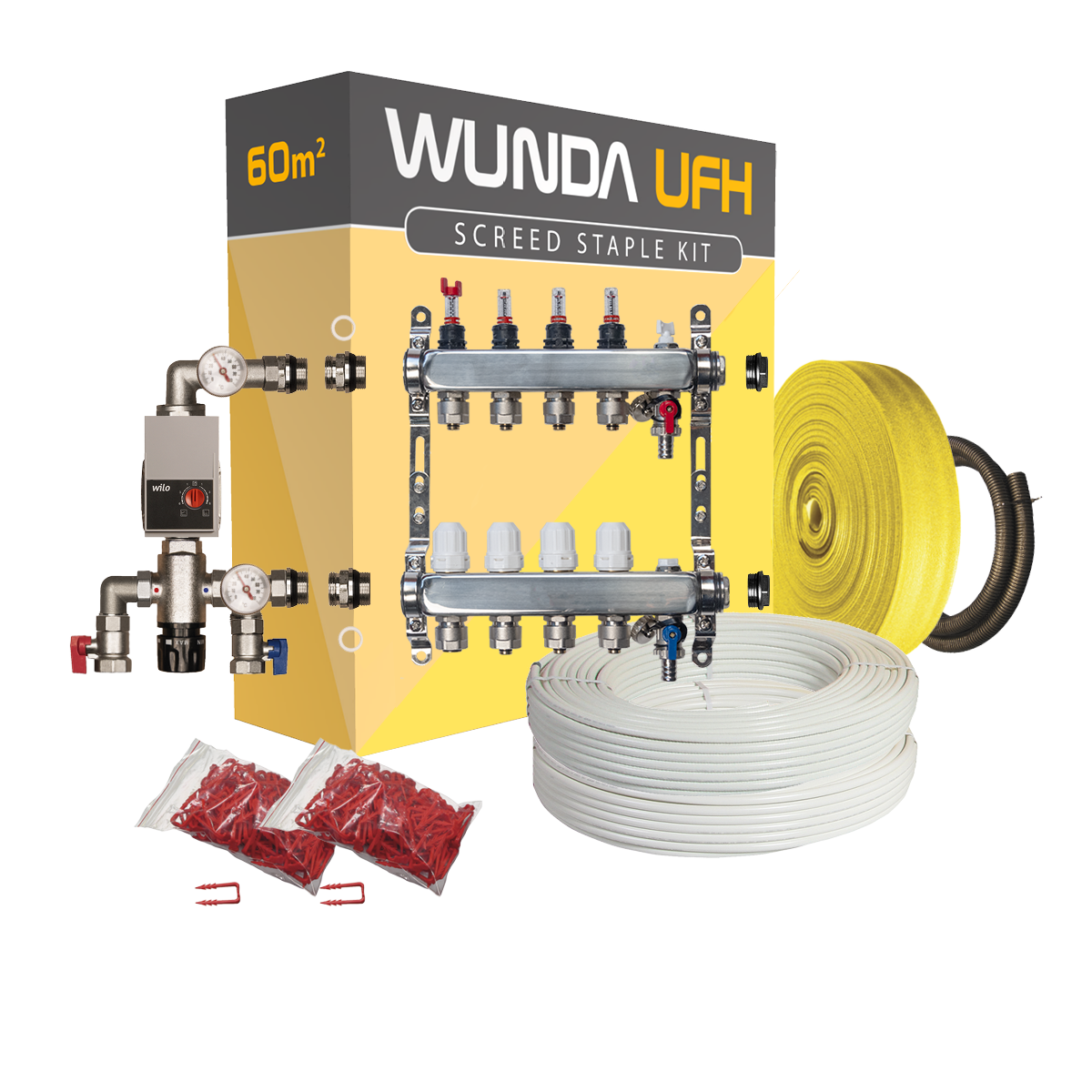

Before OVERFLOOR heating the traditional method (UFH) was to bury floor heating pipes into a thick screed and gently heat the slab to create a heat store which gently emitted heat into the room above.

Traditional UFH is ideal for new builds where access to the insulation below was easily gained, however not so simple for a renovation or when extending a home.

The upheaval and expense of removing an existing screed floor is often prohibitive and an off-put to both homeowners and installers alike. Plus the added expense, mess and drying times of a new screed resulted in multiple visits from the installer to fit and commission the system.

Wunda OVERFLOOR can be installed onto virtually any sound, level, existing floor with minimal disruption. No removal of existing floors, no mess weight or drying times associated with a screed system.

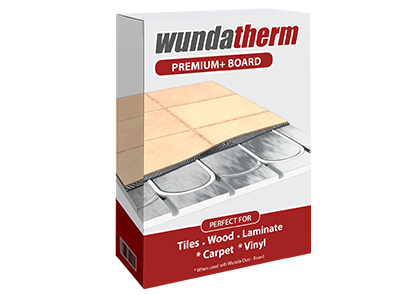

With such a huge choice of OVERFLOOR boards and suppliers now selecting the right board, manufactured from the right material is important. Also consideration to the property type and performance the customer requires Is Important when choosing the correct boards.

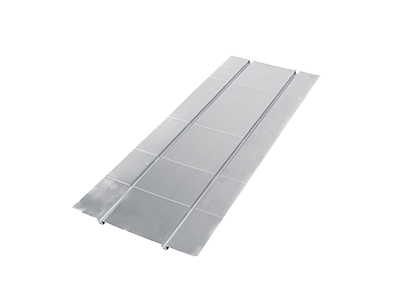

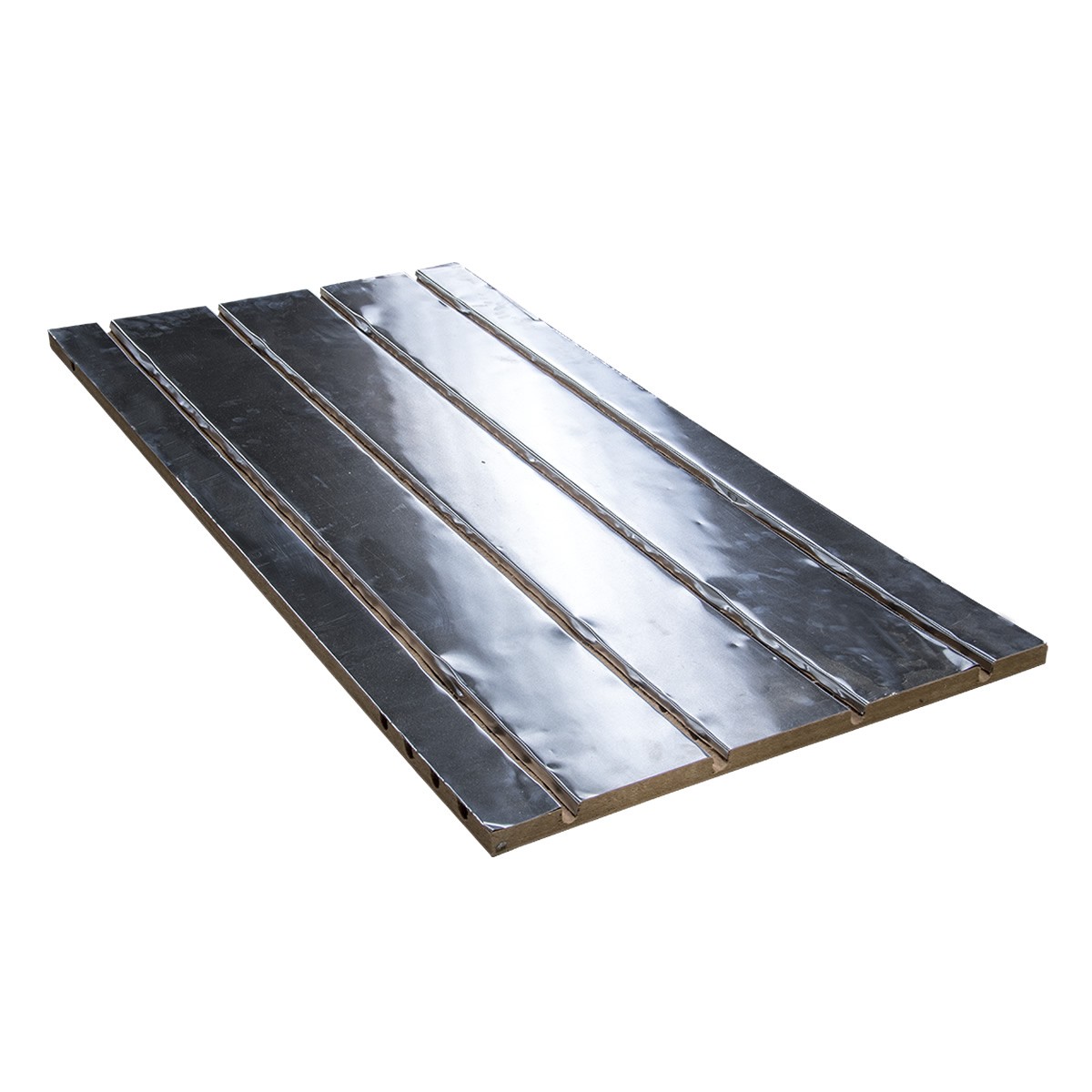

How the aluminium coating thickness affects performance

A plain board with no aluminium will not be as quick to respond as a board with a 200 micron thick aluminium coating to spread the heat rapidly across the surface. Likewise a board with 45 micron thick foil will not respond as quickly and certainly would not be suitable in an older property.

The OVERFLOOR board is a carrier for the pipe below the floor surface, the aluminum coating thickness will determine how quickly and evenly heat is spread from the pipes across the floor. The thinnest Wunda offer is 50 micron thick which is really only suitable for a highly insulated new build, 100 micron thick is suitable for well insulated properties where rapid response is not required and 200 micron thick is for all property types and will give optimum performance with a rapid response. Surprisingly, tests have indicated that using aluminum thicker than 200 microns will not result in greater performance.

Types of OVERFLOOR board

The choice of OVERFLOOR board construction material is also something to consider and choosing the correct board for your intended floor finish is very important.

Wunda EPS Boards

Constructed from Expanded Polystyrene – EPS boards are lightweight and easy to cut with a craft knife or fine toothed saw. They come in many different grades of compressive strength measured in kPa. The softest being:

100kPa which will require a backer board to support laminate, wood or carpet.

200kPa is suitable for supporting wood and laminate as a final floor finish.

400kPa is available as a super strength board having approval for tiling directly onto. Choosing a Wunda 400kPa approved board means that you can tile directly onto the board and a screed is not required keeping build up height and costs to a minimum.

Wunda Acoustic Fibre OVERFLOOR boards

Wunda Acoustic Overfloor boards are UKAS Accredited and laboratory tested to BS EN ISO 10140-3 improvement in impact sound isolation with an up to 59dB improvement. Acoustic fibre boards reduce the transmission of both impact and airborne noise to rooms situated directly below the installation and therefore are ideal for use in flats and apartments. Acoustic boards are generally recommended for use with Wood & Laminates.

Wunda Chipboard OVERFLOOR boards

These provide an extremely rigid and stable base that will be compatible with virtually all floor finishes but are generally used when using heavyweight natural stone or Marble tiles.

Please note: If soft floor coverings such as carpet, vinyl or luxury vinyl’s such as Karndean, are to fitted, then all types of Overfloor boards must either be over-boarded with a suitable backer board or the use of a light renovation screed can be used on EPS kPa400 & Chipboard to provide a flat surface to prevent the pipe channels from ‘ghosting’ through.

Fixing methods for OVERFLOOR boards

Wunda always recommend that OVERFLOOR solutions are bonded/fixed to the subfloor, this is to prevent any movement or squeaks later on when the final floor has been laid. Wunda EPS boards can be quickly and securely bonded to the sub floor using Wunda contact spray adhesive, specifically designed for use in the building trade to bond EPS to concrete and wood. Which means that the floor heating pipe can be laid straight away. Available in handy 500ml spray cans or for larger jobs a 22L canister and spray lance which has a two year shelf life! Alternatively our Mapei acrylic adhesive can be used. Chipboard and Acoustic boards will require glue and or screws to fix the boards in place again to prevent any movement of squeaking underfoot and it also allows the pipe can to lay straight away saving time on-site.

Which Pipe is best?

The profile thickness of an Overfloor board will dictate the diameter pipe needed to be installed and will typically range from 12mm pipe in 16/17mm profile boards and 16mm pipe in 20/22mm boards. 12mm pipes are set at 120mm pipe spacing and 16mm pipe at 150mm pipe spacing in all Wunda Overfloor boards for optimum performance.

In our experience the lower profile systems are better suited to smaller areas such as bath, shower and utility rooms and can struggle to cope with larger area rooms and pipe lengths are restricted to shorter lengths resulting in bigger manifolds and more transitional pipes. Whereas 16mm pipes are perfect for larger projects, main living areas where the greater volume of warm water within the pipe delivers rapid response performance and efficiency.

Important considerations

When partnered with any natural wood floor finish (and some laminates), the surface temperature of the floor must never exceed 27° C as this could make the flooring warp or split.

This is easily remedied by fitting a floor probe that’s linked to the thermostat. This will automatically turn off the heating to the room just before this temperature is reached. Any good supplier will offer this option as part of their systems if they are aware of the type of floor finish that will be fitted.

Wunda Overfloor heating is a quick and simple floor heating solution with great results, and fantastic customer feedback. Whether you are new to installing or a seasoned pro for a free no obligation quote simply send your plans to sales@wundatrade.co.uk .